Optimum Surfaces

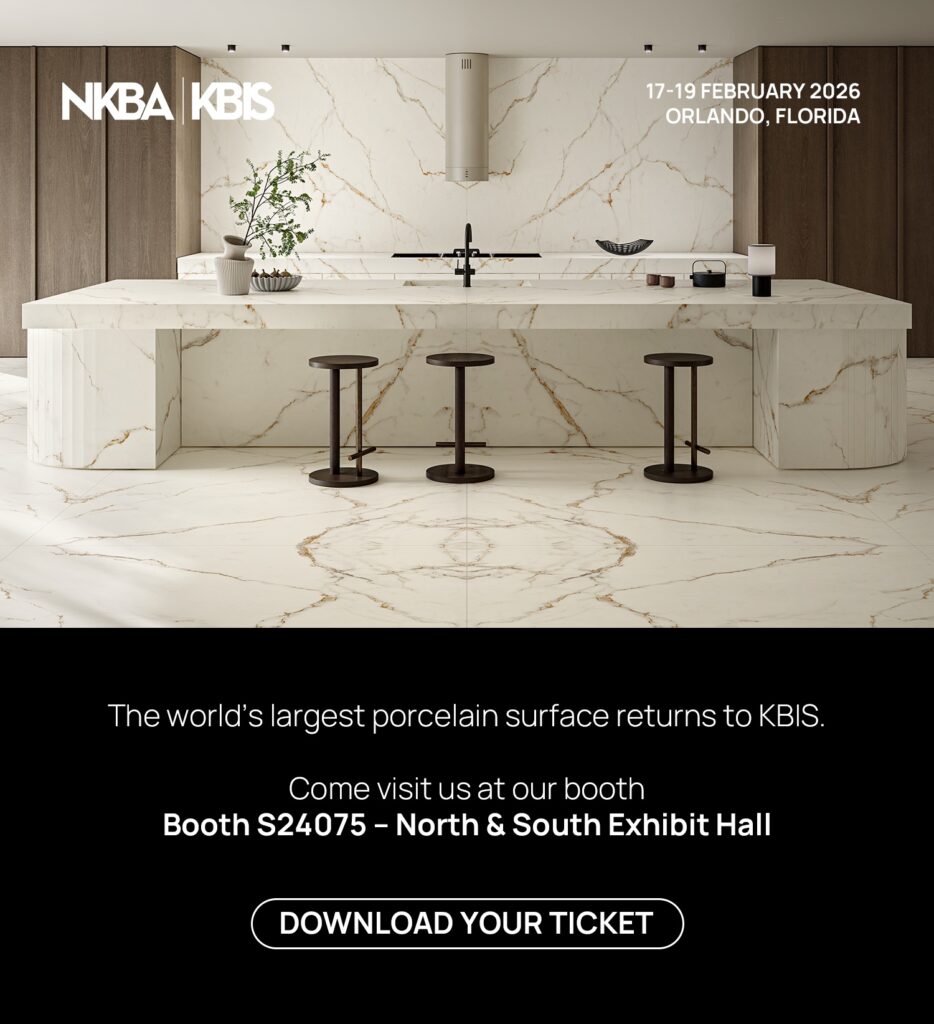

Optimum Surfaces was created in response to a scenario of continuously evolving style, architecture, and design. Optimum Surfaces porcelain stoneware extra-large slabs offer the perfect fusion of aesthetics and functionality: an unprecedented pioneering achievement. The unique, distinctive size of Optimum Surfaces slabs – 1840×3300 mm –is, in fact, an exclusive innovation: they are, quite simply, the largest slabs available on the market.

This new frontier in porcelain stoneware slabs was made possible by a significant plan of investments put in place by Optimum Surfaces’ owner Ceramica del Conca S.p.a. and based on the following key aspects: environmental sustainability, innovative products, uncompromising aesthetics, and efficient production.

Extra-large stoneware slabs that pair design and performance

Optimum Surfaces products are created by combining a series of strengths: premium-quality raw materials, pioneering technologies with a strong focus on sustainability, a sophisticated aesthetic, and an extensive knowledge of designing and engineering surfacing materials.

The resulting top-end high-performance surfacing materials offer unprecedented ability to meet all design and furnishing needs and provide custom solutions for all the professionals involved along the supply chain.

Optimum Surfaces technology

The uniquely sized (1840×3300mm) rectified slabs are available in three thicknesses, 7, 12 and 20mm. The 20mm-version offers the most advanced performance and is available in a large number of products and finishes, in order to allow customers as wide a range of choice as possible.

The slabs are shaped by a high-performance system which ensures the raw materials are compacted gradually and evenly. Advanced testing techniques are conducted using sophisticated scanners to check the slabs prior to firing and confirm they meet quality requirements.

Next, the Optimum Surfaces slabs are fired in a next-generation kiln designed and configured specifically for extra-large and extra-thick materials.

This firing process involves temperatures of up to 1220°C, to guarantee the high performance levels that are characteristic of porcelain stoneware.

These brand-new technologies, combined with the experience and ability of the Optimum Surfaces engineers, make the slabs easy to machine and process and therefore, simple to use and amenable to multiple applications.